How To Properly Fight A Lithium-ion Battery Fire

How To Properly Fight A Lithium-ion Battery Fire

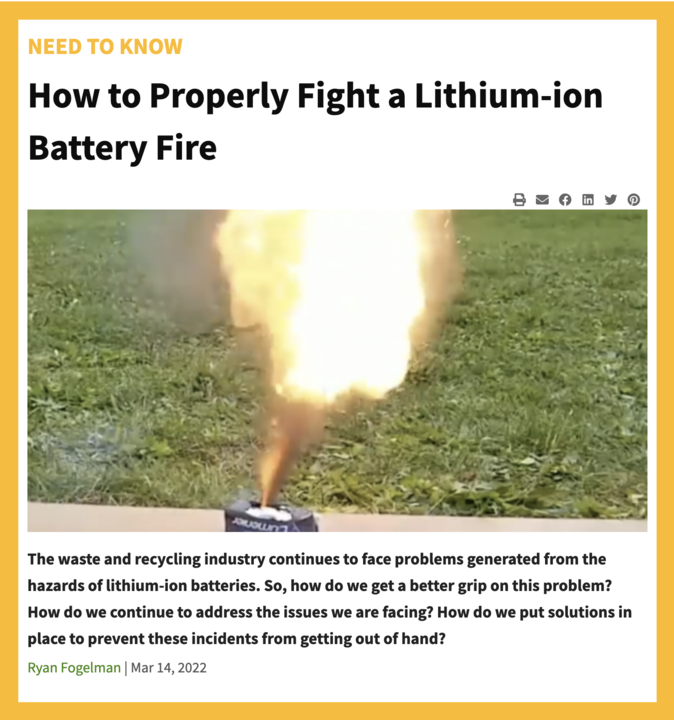

The waste and recycling industry continues to face problems generated from the hazards of lithium-ion batteries. So, how do we get a better grip on this problem? How do we continue to address the issues we are facing? How do we put solutions in place to prevent these incidents from getting out of hand? Learn the answers to these questions and more in this month’s column.

January and February 2022 Fire Data

In January and February 2022, we encountered 50 reported fire incidents at our waste and recycling facilities in the U.S. and Canada. This marks the worst January and February for fires since I begin reporting these fire incidents in 2016. Of these reported incidents, half occurred at waste, paper and plastic operations, 15 at scrap metal facilities, four at rubber recycling operations, one at a construction and demolition (C&D) operation, one at an organics site and one at a hazardous materials facility.

Traditionally, the months of January and February have been our lowest months for fires. However, this year has been unique. With 50 fire incidents, we are only 20 percent above the average of 41 we experienced in the past five years. The issue is that when we see this number coming off our worst year for fire events in 2021, it feels like we are experiencing a continuation of a disturbing trend.

At Fire Rover’s 300-plus client operations, January was a light month. We only responded to 36 events in January and 58 in February. The fact that January and February were relatively light months for our Fire Rover clients makes sense as these fires incidents are in line with what we see historically. But in my opinion, this fact only makes these high fire incidents more disturbing.

It's important to note that I only track reported fire incidents, and I define “reported” as fires publicly reported by a news agency. These reported incidents are typically larger fire events that garner the media’s attention, but we all know there are more fires that don’t get covered by the media.

While I do not track catastrophic losses versus smaller fires, it would be logical to assume that although there are fewer fire incidents, the fires seen this January and February were bigger than in past years.

Lithium-ion Batteries 101

I often get asked what is causing the growth in fire incidents, and the answer is quite simple: lithium-ion batteries.

According to my colleague Ronald Butler, the Jedi Master of lithium-ion batteries, “Lithium batteries are capable of spontaneous ignition and subsequent explosion from overheating. That may be caused by electrical shorting, rapid discharge, overcharging, manufacturers’ defect, poor design or mechanical damage, among other causes. Overheating results in a process called thermal runaway, which is a reaction within the battery causing internal temperature and pressure to rise at a quicker rate than can be dissipated.”

Most research and discussion around lithium-ion battery dangers have been focused on large energy storage operations. These are major installations where batteries are part of a bigger infrastructure, such as power banks where large amounts of power is stored. The wake-up call for these hazards was an incident in Surprise, Ariz., a few years back.

At Arizona Public Service’s McMicken Energy Storage facility, racks of battery modules were stacked from the floor to the ceiling. In one of those racks, a faulty battery cell had essentially shorted out, overheated and damaged other nearby modules. This chain of events led to what is called thermal runway, which is a buildup of heat that can lead to a fire.

While the building had a fire suppression system, it was only designed to extinguish a small fire that could lead to thermal runway, not batteries that were already in thermal runway. So even though the fire suppression system discharged, the batteries continued to overheat with no flames. This eventually led to a buildup of flammable gasses, which came in contact with a heat source or spark and then exploded when the firefighters opened the door to enter the building.

To prevent incidents like this in the future, we need to find solutions that have early detection not only of flames but of heat, smoke and gas. Additionally, in an instance where thermal runway is already achieved, we need the fire professionals to focus on stopping the chain reaction.

Recognizing these needs, we developed Fire Rover’s sprinkler replacement for lithium-ion battery operations. With this system, we try to catch fires as early in the process as possible. Then we spray the hot spot to try and stop the process of thermal runway and spray the collateral assets, which can help stop the chain of events. We also help firefighters remain in a defensive position outside of the operation, so they don’t have to risk experiencing something similar to what happened in the Surprise incident.

So, if you are not in the electronic scrap, large storage battery or electric vehicle battery business, why do you care? Because in the waste and recycling industry, we are seeing this play out in our infrastructure on a daily basis. Albeit on a smaller scale.

Unlike in large storage operations, we are causing the batteries to explode by the way they are treated. Our process uses compaction, shredding, heavy equipment and exposure to elements, which can cause batteries in our personal storage and personal electronics equipment to become damaged.

Check out the below video of a truck running over a battery.

In this incident, you can clearly see the loader drive over the batteries that exploded under the tire. There is also another truck dumping cardboard right next to the fire on the tip floor. This scenario is one that plays out daily on our tip floors as well as in scrap metal facilities and C&D operations.

However, these fires don’t always happen directly from a truck’s force. Watch the video below to see how a battery started to heat and ignite on top of a pile.

Incidents like this take more than water to extinguish, and that’s why we use an environmentally friendly cooling agent that helps slow down or eliminate thermal runway and turns collateral material into a sponge, so the fire burns itself out and breaks the fire chain.

When it comes to combating electric vehicle (EV) fires, we often hear about the dunk method. According to Tony Markovich of Autoblog, “Because of the chemistry of the lithium-ion batteries found in most EVs, their chemical fires can take massive amounts of water to put out and keep out. So, instead of dousing a car with water, it's smarter to put it in water, where it will safely be stifled.”

This is an interesting solution, but there are many problems with this method, one of the most important being that it’s not timely. In the U.S., we would need a tank strategically placed across our nation’s roads, which would seem to be an excessive cost.

Since this solution isn’t quite realistic for us, we are instead focusing on proper separation and firewalls when it comes to dealing with the hazards of lithium-ion batteries. Separation makes sense when we are dealing with lithium-ion battery operations and a large bank of batteries for power supplies specifically. But in waste and recycling operations where we are dealing with smaller, more disbursed hazards, we need to focus on reaction time and stopping the collateral risks. In my opinion, the industry’s current best practices around pile size and separation are correct as long as the proper solution for early detection and response is in place.

Conclusion

Based on the national conversation around battery hazards, we are still in the wild west, as there has been very little agreement on how to properly fight the new hazards of lithium-ion batteries. We have only been dealing with these fires for less than a decade, but the manta of “water, water, water” is slowly being replaced with early detection, proper verification and proper response based on the hazards. Not all battery risks and fires are the same; therefore, we need different solutions that make sense for the level of risk and exposure we face.

On that note, if you would like to learn more about the topic, Ron and I, along with David Naughton will be presenting at the Southeast Recycling Conference & Trade Show, March 16th in Destin, Florida. Ron’s presentation should be especially interesting as he outlines the full story of the “Morris, IL battery warehouse fire” that occurred last year. He also will discuss the lesson learned from the event including the fire department response criteria adjustment, redesign of fire control metrics, and the development of "flash" codes that will absolutely impact the battery recycling industries. Full details are available at www.southeastrecycling.com.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman speaks regularly on the topic of the scope of fire problems facing the waste and recycling industries, detection solutions, proper fire planning and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at rfogelman@firerover.com)

Comments

Post a Comment