Combustible Dust Explosions Common to Baghouses

From our friends at BS&B and Baghouse.com: http://www.baghouse.com/2013/10/15/introduction-to-combustible-dust-explosions-common-to-baghouses/

Guest Post By Bevin Sequeira

BS&B Safety Systems (Asia Pacific) Pte Ltd.

A Dust Explosion is the fast combustion of dust particles suspended in the air in an enclosed location. Coal dust explosions are a frequent hazard in underground coal mines, but dust explosions can occur where any powdered combustible material is present in an enclosed atmosphere or, in general, in high enough concentrations of dispersed combustible particles in atmosphere.

Dust explosions can lead to loss of life, injury, damage property and environmental damage as well as consequential damage such as business interruption losses.

Dust explosions involve most commonly “dust”, i.e. fine material. This can be the product being handled or it can be produced as the result of the processing. However, in many cases fine dust is present in material that is otherwise too coarse to pose a dust explosion hazard, either as part of the product or generated by attrition during handling or transport. Therefore, while replacing a fine material by a granular one (such as pellets or flakes) will reduce the dust explosion hazards, this may not be sufficient to eliminate the hazards. Similarly, a user of a granular material may process it to a particle size that introduces dust explosion hazards.

Many dust explosions that occur in process plants are relatively small, leading to limited damage. However, under the right circumstances, even small explosions can escalate into major incidents. This is most commonly the case when secondary dust explosions happen. The typical scenario is that a small “primary” explosion raises a dust cloud, often from dust deposited over time on plant surfaces, and ignites the resulting dust cloud. This “secondary” explosion takes place where often people are present, placing them in immediate danger. Secondary dust explosions can form a chain reaction that can run through a facility as long as fuel is present, leading to widespread devastation.

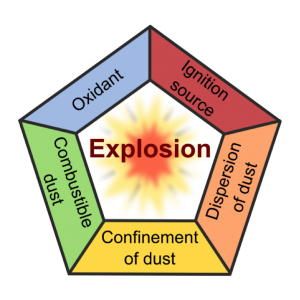

There are five necessary conditions for a dust explosion or deflagration:

1. Presence of Combustible Dust

2. Dust suspended in the air at a high concentration

3. There is an Oxidant (typically atmospheric oxygen)

4. There is an Ignition source ( Either Flames & hot surfaces, Spontaneous Ignition, Friction sparks, Static Electricity, Electrical Equipment’s, etc.)

5. Confinement (enclosed location)

Many materials which are commonly known to oxidize can generate a dust explosion, such as coal, sawdust. The dust can arise from activities such as transporting grain and indeed grain silos do regularly have explosions. Mining of coal leads to coal dust and flour mills likewise have large amounts of flour dust as a result of milling. A gigantic explosion of flour dust destroyed a mill in Minnesota on May 2nd, 1878, killing 18 workers at the Washburn A Mill.

To support combustion, the dust must also consist of very small particles with a high surface area to volume ratio, thereby making the collective or combined surface area of all the particles very large in comparison to a dust of larger particles. Dust is defined as powders with particles less than about 500 microns in diameter, but finer dust will present a much greater hazard than coarse particles by virtue of the larger total surface area of all the particles.

Dusts have a very large surface area compared to their mass. Since burning can only occur at the surface of a solid or liquid, where it can react with oxygen, this causes dusts to be much more flammable than bulk materials. For example, a 1 kg sphere of a material with a density of 1g/cm3 would be about 27 cm across and have a surface area of 0.3 m2. However, if it was broken up into spherical dust particles 50µm in diameter (about the size of flour particles) it would have a surface area of 60 m² This greatly increased surface area allows the material to burn much faster, and the extremely small mass of each particle allows it to catch on fire with much less energy than the bulk material, as there is no heat loss to conduction within the material. When this mixture of fuel and air is ignited, especially in a confined space such as a warehouse or silo, a significant increase in pressure is created, often more than sufficient to demolish the structure.

Even materials that are traditionally thought of as non-flammable, such as aluminium, or slow burning, such as wood, can produce a powerful explosion when finely divided, and can be ignited by even a small spark.

Primary dust explosions: occur inside process plant or similar enclosures and are generally controlled by pressure relief through purpose-built ducting to atmosphere.

Secondary dust explosions: are the result of dust accumulation inside the factory being disturbed and ignited by the primary explosion, resulting in a much more dangerous uncontrolled explosion inside the workplace.

Historically, fatalities from dust explosions have largely been the result of secondary dust explosions.

Best engineering control measures which can be found in the National Fire Protection Association (NFPA) Combustible Dust Standards include:

• Oxidant Concentration Reduction

• Deflagration venting

• Deflagration pressure containment

• Deflagration suppression

• Deflagration venting through a dust retention and flame-arresting devices

• Spark Detection & Extinguishing Systems

Explosive Materials:

The following materials are prone to dust explosions.

• Coal

• Fertilizer

• Cosmetics

• Pesticides

• Plastic & plastic resins

• Wood

• Charcoal

• Detergents

• Foodstuffs (sugar, flour, milk powder, etc.)

• Ore dusts

• Metal dusts

• Graphite

• Dry industrial chemicals

• Pigments

• Cellulose

Industrial Equipment:

Typical industrial equipment’s that require explosion protection.

• Dust Collectors

• Dryers

• Cyclones

• Crushers

• Grinders

• Silos

• Pulverisers

• Conveyors

• Conveyor ducts

• Screw conveyors

• Bucket Elevators

• Furnaces

• Hoppers

• Bins

Dust explosions are often exacerbated by propagation through ducting between process equipment, frequently via dust collector pickup and return ducting. Moe widespread use of effective deflagration isolation devices in such ducting would clearly be beneficial in mitigating the damage and injuries from these propagating dust explosions. (See article Dust Collector Fire and Explosion Highlights Need for Combustible Dust Considerations In System Designs)

Secondary dust explosions in processing buildings probably cause the largest numbers of dust explosion fatalities and injuries. One crucial aspect of secondary dust explosion prevention and mitigation is greater awareness of good housekeeping and maintenance practices to prevent particulate leakage from equipment and subsequent accumulations of dust deposits in large areas of the buildings.

Bevin Sequeira holds a B.E. (Mechanical) degree & a MBA (Marketing) specializing in business development & enhancement of virgin markets all over the globe. With over two decades of international working experience in the industry, Bevin's knowledge of the industry spans various sectors like Iron & Steel, Foundry, Chemicals & Fertilizer, Power, Food, Pharma, etc. He is currently serving as Regional Sales Manager at http://www.bsbipd.com" target="_blank">BS&B Safety Systems

(Asia Pacific) Pte Ltd. specialising in Combustible Dust Explosion Protection Systems & Risk Management. In his spare time, Bevin likes to read, travel, socialise & collaborate with business houses for M&A, Management Consultancy, etc.

Introduction to Combustible Dust Explosions Common to Baghouses

Guest Post By Bevin Sequeira

BS&B Safety Systems (Asia Pacific) Pte Ltd.

Introduction to Dust Explosions

A Dust Explosion is the fast combustion of dust particles suspended in the air in an enclosed location. Coal dust explosions are a frequent hazard in underground coal mines, but dust explosions can occur where any powdered combustible material is present in an enclosed atmosphere or, in general, in high enough concentrations of dispersed combustible particles in atmosphere.

Dust explosions can lead to loss of life, injury, damage property and environmental damage as well as consequential damage such as business interruption losses.

Dust explosions involve most commonly “dust”, i.e. fine material. This can be the product being handled or it can be produced as the result of the processing. However, in many cases fine dust is present in material that is otherwise too coarse to pose a dust explosion hazard, either as part of the product or generated by attrition during handling or transport. Therefore, while replacing a fine material by a granular one (such as pellets or flakes) will reduce the dust explosion hazards, this may not be sufficient to eliminate the hazards. Similarly, a user of a granular material may process it to a particle size that introduces dust explosion hazards.

Many dust explosions that occur in process plants are relatively small, leading to limited damage. However, under the right circumstances, even small explosions can escalate into major incidents. This is most commonly the case when secondary dust explosions happen. The typical scenario is that a small “primary” explosion raises a dust cloud, often from dust deposited over time on plant surfaces, and ignites the resulting dust cloud. This “secondary” explosion takes place where often people are present, placing them in immediate danger. Secondary dust explosions can form a chain reaction that can run through a facility as long as fuel is present, leading to widespread devastation.

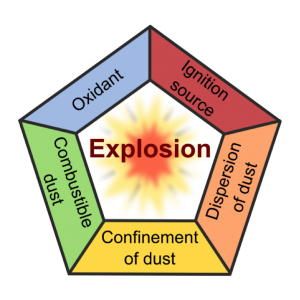

Conditions for Dust Explosion

There are five necessary conditions for a dust explosion or deflagration:

1. Presence of Combustible Dust

2. Dust suspended in the air at a high concentration

3. There is an Oxidant (typically atmospheric oxygen)

4. There is an Ignition source ( Either Flames & hot surfaces, Spontaneous Ignition, Friction sparks, Static Electricity, Electrical Equipment’s, etc.)

5. Confinement (enclosed location)

Many materials which are commonly known to oxidize can generate a dust explosion, such as coal, sawdust. The dust can arise from activities such as transporting grain and indeed grain silos do regularly have explosions. Mining of coal leads to coal dust and flour mills likewise have large amounts of flour dust as a result of milling. A gigantic explosion of flour dust destroyed a mill in Minnesota on May 2nd, 1878, killing 18 workers at the Washburn A Mill.

To support combustion, the dust must also consist of very small particles with a high surface area to volume ratio, thereby making the collective or combined surface area of all the particles very large in comparison to a dust of larger particles. Dust is defined as powders with particles less than about 500 microns in diameter, but finer dust will present a much greater hazard than coarse particles by virtue of the larger total surface area of all the particles.

Sources of Ignition

There are many sources of ignition and a naked flame need not be the only one: over one half of the dust explosions were from non-flame sources. Common sources of ignition include electrostatic discharge friction arcing from machinery or other equipment or hot surfaces such as overheated bearings. However it is often difficult to determine the exact source of ignition post-explosion. When a source cannot be found, it will often be cited as static electricity. Static charges can occur by friction at the surfaces of particles as they move against one another, and build up to levels leading to a sudden discharge.Combustible Dust Concentrations:

As with gases, dust is combustible with certain concentration parameters. These parameters vary widely across the spectrum. Highly combustible dust can form a flammable mixture with less than 15 g/m3.Mechanism of dust explosions:

Dusts have a very large surface area compared to their mass. Since burning can only occur at the surface of a solid or liquid, where it can react with oxygen, this causes dusts to be much more flammable than bulk materials. For example, a 1 kg sphere of a material with a density of 1g/cm3 would be about 27 cm across and have a surface area of 0.3 m2. However, if it was broken up into spherical dust particles 50µm in diameter (about the size of flour particles) it would have a surface area of 60 m² This greatly increased surface area allows the material to burn much faster, and the extremely small mass of each particle allows it to catch on fire with much less energy than the bulk material, as there is no heat loss to conduction within the material. When this mixture of fuel and air is ignited, especially in a confined space such as a warehouse or silo, a significant increase in pressure is created, often more than sufficient to demolish the structure.

Even materials that are traditionally thought of as non-flammable, such as aluminium, or slow burning, such as wood, can produce a powerful explosion when finely divided, and can be ignited by even a small spark.

Terminology:

Dust explosions may be classified as being either primary or secondary in nature.Primary dust explosions: occur inside process plant or similar enclosures and are generally controlled by pressure relief through purpose-built ducting to atmosphere.

Secondary dust explosions: are the result of dust accumulation inside the factory being disturbed and ignited by the primary explosion, resulting in a much more dangerous uncontrolled explosion inside the workplace.

Historically, fatalities from dust explosions have largely been the result of secondary dust explosions.

Best engineering control measures which can be found in the National Fire Protection Association (NFPA) Combustible Dust Standards include:

• Oxidant Concentration Reduction

• Deflagration venting

• Deflagration pressure containment

• Deflagration suppression

• Deflagration venting through a dust retention and flame-arresting devices

• Spark Detection & Extinguishing Systems

Explosive Materials:

The following materials are prone to dust explosions.

• Coal

• Fertilizer

• Cosmetics

• Pesticides

• Plastic & plastic resins

• Wood

• Charcoal

• Detergents

• Foodstuffs (sugar, flour, milk powder, etc.)

• Ore dusts

• Metal dusts

• Graphite

• Dry industrial chemicals

• Pigments

• Cellulose

Industrial Equipment:

Typical industrial equipment’s that require explosion protection.

• Dust Collectors

• Dryers

• Cyclones

• Crushers

• Grinders

• Silos

• Pulverisers

• Conveyors

• Conveyor ducts

• Screw conveyors

• Bucket Elevators

• Furnaces

• Hoppers

• Bins

Conclusions

Many reported dust explosions have originated in common powder and bulk solids processing equipment such as dust collectors, dryers, grinders/pulverisers, and blenders. Electrostatic discharges are frequently cited as the ignition source for dust collector explosions, whereas particulate overheating is the most common ignition source in dryer explosions, and friction/impact heating associated with tramp metal or misaligned parts is probably the most frequent ignition source in grinder/pulveriser explosions.Dust explosions are often exacerbated by propagation through ducting between process equipment, frequently via dust collector pickup and return ducting. Moe widespread use of effective deflagration isolation devices in such ducting would clearly be beneficial in mitigating the damage and injuries from these propagating dust explosions. (See article Dust Collector Fire and Explosion Highlights Need for Combustible Dust Considerations In System Designs)

Secondary dust explosions in processing buildings probably cause the largest numbers of dust explosion fatalities and injuries. One crucial aspect of secondary dust explosion prevention and mitigation is greater awareness of good housekeeping and maintenance practices to prevent particulate leakage from equipment and subsequent accumulations of dust deposits in large areas of the buildings.

About the Author

About the Author

Bevin Sequeira holds a B.E. (Mechanical) degree & a MBA (Marketing) specializing in business development & enhancement of virgin markets all over the globe. With over two decades of international working experience in the industry, Bevin's knowledge of the industry spans various sectors like Iron & Steel, Foundry, Chemicals & Fertilizer, Power, Food, Pharma, etc. He is currently serving as Regional Sales Manager at http://www.bsbipd.com" target="_blank">BS&B Safety Systems

(Asia Pacific) Pte Ltd. specialising in Combustible Dust Explosion Protection Systems & Risk Management. In his spare time, Bevin likes to read, travel, socialise & collaborate with business houses for M&A, Management Consultancy, etc.

Comments

Post a Comment